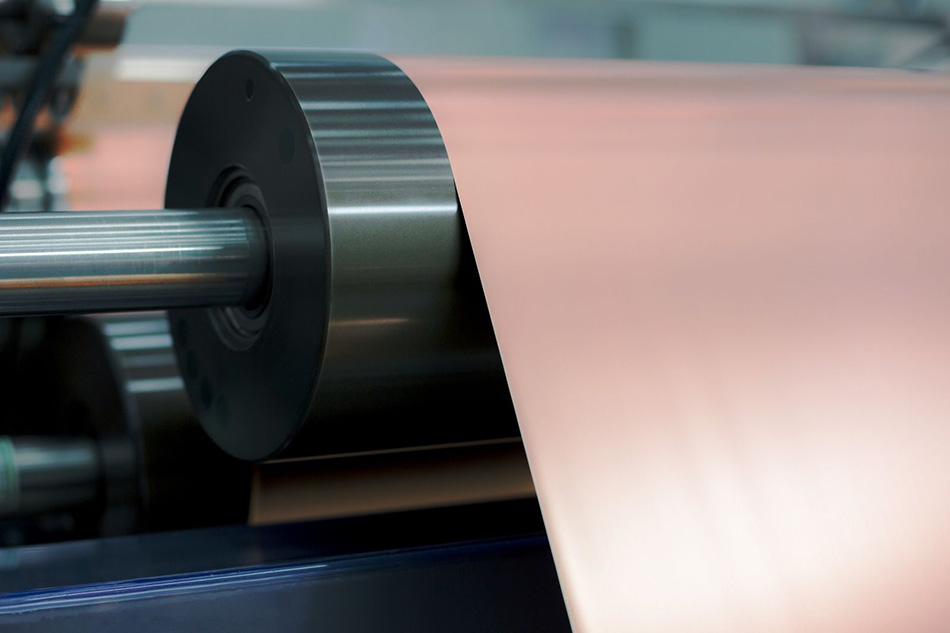

Hte hipper foil foil

●Botenya: 12um 15um 18um 35um 105um

●Bophara ba naha: 1290, e ka khaola ka kopo ea boholo

●Sephutheloana sa mapolanka

●Boleng bo thehiloe ho GB / T5230-1995 le IPC-4562 misterard

●Id: 76 mm, 152 mm

●Bolelele: E ratoang

●Sampole e ka fana ka faele

Khamphani e thehile lijo-thollo tse ntle le foil ea koporo e matla ea koporo e matla ea bokhopo bo tlase le ts'ebetso e phahameng ea mocheso. Sena se tšoara lithollo tse ntle le ho feta tse ntle ebile li ka thibela linako tse bohloko tse bakoang ke khatello ea maikutlo le ka ntle ea boto e mengata. Ka boemo bo tlase ba ho ba le bokhabane bo thata le ho hlohlona hantle, ho sebetsa ka bongata bo phahameng le bosesane. Ka matla a matle haholo, ho a thusa ho fetoha le maemo 'me haholo ho sebelisoa haholo PCB ea k'hemiriileer hammoho le poleiti ea Flex. Ka ho ba le boiketloli le ho ba thata, ha ho thellise habonolo pheletsong kapa lesa, ho ntlafatsa lebelo la thuto ea thuto.

●Foil e phekotsoeng ka bohlooho kapa bofubelu

●Matla a Phahameng

●Ho Etletsoa Hantle

●Khanyetso e ntle haholo

●Anti Fouil e oela ka nako e phahameng ka mocheso o phahameng

●Ho mela e phahameng kamora ho phekoloa ka mocheso o phahameng kapa o kholoanyane.

●Thepa ea Phahameng.

●E sebetsang molemong oa ho sisinyeha ha poleiti.

●Boto ea Polyimide

●EPOYY Board

●Cem-3, FR-4, Fydrocarbon substrate substrate

●Multilayer Board

●High TG, Free-Free-Free-Free-Free-Free le Halogen-Free Tg

●Khatiso e Ntle ea Boithati

| Classified | Yuniti | TLHOKOMELISO | Mokhoa oa liteko | |||||

| Botenya ba lebitso | Um | 12 | 18 | 35 | 70 | 105 | IPC-4562a | |

| Boima ba sebaka | G / M² | 107 ± 5 | 153 ± 7 | 285 ± 10 | 585 ± 20 | 870 ± 30 | IPC-TM-650 2.2.12.2 | |

| Bohloeki | % | ≥99.8 | IPC-TM-650 2.3.15 | |||||

| ho ba thata | Lehlakoreng le leng (Ra) | ս m | ≤0.43 | ≤0.43 | ≤0.43 | ≤0.43 | ≤0.43 | IPC-TM-650 2.3.17 |

| Matte lehlakoreng (rz) | um | ≤6 | ≤8 | ≤10 | ≤15 | ≤20 | ||

| Matla a tšepe | Rt (23 ° C) | Mpa | ≥207 | ≥207 | ≥276 | ≥276 | ≥276 | IPC-TM-650 2.4.18 |

| HT (180 ° C) | ≥103 | ≥103 | ≥138 | ≥138 | ≥138 | |||

| Emplation | Rt (23 ° C) | % | ≥2 | ≥2 | ≥3 | ≥3 | ≥4 | IPC-TM-650 2.4.18 |

|

| HT (180 ° C) | ≥2 | ≥2 | ≥2 | ≥3 | ≥3 | ||

| Restudition | Ω.G / M MOTSOE | ≤0.17 | ≤0.166 | ≤0.16 | ≤0.162 | ≤0.162 | IPC-TM-650 2.5.14.14 | |

| Matla a peel (FR-4) | N / mm | ≥0.9 | ≥1.1 | ≥1.4 | ≥2.0 | ≥2.0 | IPC-TM-650 2.4.8 | |

|

| lbs/in | ≥5.1 | ≥6.3 | ≥8.0 | ≥11.4 | ≥11.4 | ||

| Pinholes le Porosity | Palo | No | IPC-TM-650 2.1.2 | |||||

| Anti-oxidization | Rt (23 ° C) |

| 180 |

| ||||

| Rt (200 ° Cer) |

| 40 |

| |||||

Bophara ba naha, 1295 (± 1) MM ea bophara: 200graphmmmm. May ho latela kopo ea bareki ea moreki.

Re leka matla a peel le FR-4 (TG140) Ererivererererererere, ka kopo e nchafatsa ka PP ea hau.