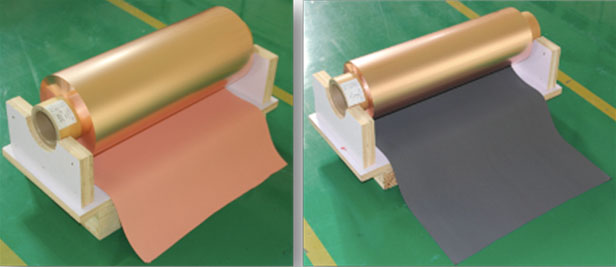

Matte Side Lefetsoe le Lebetsoeng le Lebetsoeng le ile la fapohela Frop Colper Filper e ntšo le 'mala o mofubelu

Adged e ka tlase e ne e hatisa foil ea koporo ka lehlakoreng le letšo / le matte lehlakoreng

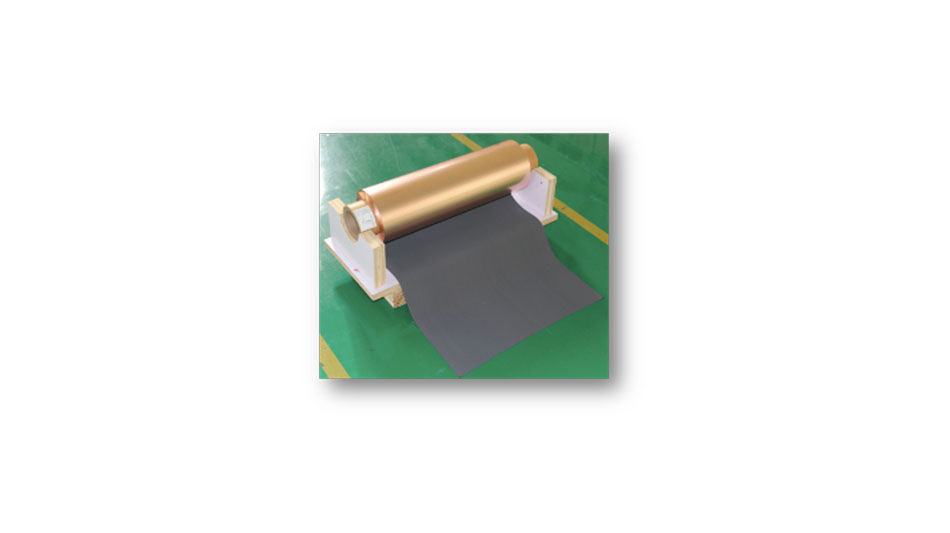

Li-coul spil coil

Nakong ea ho futhumatsa ho futhumatsa, boitsebiso boo bo tla feta maemong a mocheso o lekaneng bakeng sa ho fofa ha thepa hona joale ha ho bonolo ho tsoa nakong ea ho otlolla.

●Fori ea koporo e tsamaisoang ka mokhoa o robola ka lehlakoreng le khubelu la matte

●Foil e halikiloeng ea cogeper e halikiloeng ka lehlakoreng le letšo la matte

●Botenya: 9um 12um 18um 22um 35um ea 35umm

●Bophara: 250 ~ 630mm, bophara ba naha: 520mm, e ka khaola joalo ka kopo

●Sephutheloana sa mapolanka

●Sehlahisoa se fihlile ho litekanyetso tsa tikoloho ea ROHS

●Id: 76 mm

●Bolelele: E ratoang

●Mohlala o ka fana ka tšehetso

●Bolelele bolelele ba bolelele ba mantlha: joalo ka kopo ka kopo

●Tšela ka hare le bophara ba bophara bo ka hare: joalo ka kopo

●Ho ba le khalefo e tlase

●Ho fetoha le maemo a phahameng

●Ts'ebetso e Ntle e Ntle

●Foil e phekotsoeng e ntšo kapa e khubelu

●Foil ea sentsoeng e na le maemo a phahameng, ho na le bothata bo tlase le thepa e ntle ea 'mele le ea lik'hemik'hale.

●Etsa kopo ho FPC (e leng ho feto-fetoha Sesole sa Lihlahisoa tsa Boraro se phahameng joalo ka Aerospace, lisebelisoa tsa bongaka, liroboto, liroboto, liroboto tsa puisano le elektroniki ea puisano.

●Etsa kopo ho FPCL / Copper Copper Copper Clate

●Etsa kopo ea ho feto-fetoha ha ho feto-fetoha le maemo

●Potoloho e hatisitsoeng

| Classified | Yuniti | Mokhoa oa liteko | ||||||||||||||

| Botenya ba lebitso | Um | 9 | 12 | 18um | 35um | 22um | 50um | 70um | Mokhoa oa liteko | |||||||

| Boima ba sebaka | G / M² | 80 ± 2 | 107 ± 3 | 160 ± 4 | 311 ± 5 | 196 ± 4 | 445 ± 5 | 623 ± 5 | GB / T29847-2013 | |||||||

| Bohloeki | % | Min.99.97 | GB / T5121 | |||||||||||||

| Bokhabane | Lehlakoreng le leng (Ra) | Um | Max.0.2 | GB / T29847-2013 | ||||||||||||

| Matte lehlakoreng (rz) | Um | 0.8-1.2 | ||||||||||||||

| Matla a tšepe | RM tloaelehileng | N / mm² | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | GB / T29847-2013 | ||||||

|

|

|

|

|

| ||||||||||||

| RM 180 ° C * 30min. | ≥160 | ≥160 | ≥160 | ≥170 | ≥170 | ≥170 | ≥170 | |||||||||

| Emplation | Tloaelehileng | % | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | 101.0 | GB / T29847-2013 | ||||||

| 180 ° C * 30min | ≥7 | ≥7 | ≥8 | ≥19 | ≥9 | ≥13 | ≥20 | |||||||||

| Matla a Peel | N / mm | ≥0.8 | ≥0.8 | ≥1.0 | ≥1.2 | ≥1.0 | ≥1.4 | ≥2.0 | GB / T29847-2013 | |||||||

| Boleng ba bokapele | / | 'Mala oa junifomo,Ha ho seboko,Ha ho na scratche,Ha ho na sekoti le sa bohlokoa | ||||||||||||||

| Ho hanyetsa ka lik'hemik'hale | % | Max.5 | ||||||||||||||

| Ho hanyetsa | 200 ° C / 60min | Ha ho na ntho | Q / Tbjb004-2015 | |||||||||||||

| Lesole le hanyetsa |

| 300 ° C / 20 ha ho na lithupa | ||||||||||||||

Sehlahisoa se ho Tekanyetso ea Tishes Tindight.

Adge e alafetseng e ne e roka foil ea koporo ka balck / be e khubelu